Composite foam cores play a vital role in transportation and commercial vehicle manufacturing by combining lightweight performance with outstanding strength. They help reduce fuel consumption and emissions while improving safety, durability, and design flexibility. Sky Composites’ PVC and PET foam cores provide modern solutions for building stronger, lighter, and more sustainable vehicles.

PVC foam cores in transport and commercial vehicles

PVC foam cores are a trusted choice in transportation and commercial vehicle applications, offering the perfect balance of strength, lightness, and durability. Sky Composites’ portfolio – including MYcell, Flexcell, HYcell, and Flexcell-ECO – provides both rigid and flexible core options with excellent impact and heat resistance.

These advanced materials are widely used in commercial boats and railway vehicles, where certified quality and reliability are essential.

With DNV and ISO9001 certifications, eco-friendly production, and low resin absorption, Sky’s PVC cores ensure superior strength-to-weight ratio. To maximize manufacturing efficiency, Sky also delivers processability and turnkey kitting services, helping customers streamline production and reduce waste.

PET foam cores as a recyclable alternative

PET foam cores are rapidly emerging as a sustainable alternative in the transportation industry. Manufactured from recycled polyethylene terephthalate (PET), they combine environmental responsibility with excellent mechanical and thermal performance.

Key advantages of PET foam cores include:

- Made from recycled PET, supporting circular economy goals

- High heat resistance and strong mechanical properties for demanding applications

- Lightweight structure that reduces vehicle mass, improving fuel efficiency

- Superior thermal insulation and resistance to moisture for long-term reliability

- Extended service life in railway and marine environments

These properties make PET foam cores an ideal choice for railway vehicles and marine applications, where weight reduction, durability, and sustainability are critical to performance and efficiency.

Applications of Composite Foam Cores in Commercial Vehicles

Composite foam cores are widely used across diverse commercial vehicle applications. Their unique combination of low weight, high mechanical strength, and advanced thermal properties significantly improves vehicle performance, efficiency, and long-term durability.

Recreational Vehicles (RVs)

In the RV sector, PVC foam cores are commonly used in composite sandwich panels for walls, ceilings, and floors.

These cores provide excellent rigidity and impact resistance while remaining lightweight, which directly supports fuel efficiency during travel. Their closed-cell structure prevents moisture absorption, eliminating risks of rot and mold—critical for long-term durability and occupant comfort.

Additionally, the foam cores enhance thermal insulation and sound dampening, ensuring better climate control and reduced road noise for a more comfortable journey.

Trucks and Heavy Commercial Vehicles

For trucks, trailers, and refrigerated transport vehicles, Sky Composites’ foam cores deliver superior structural integrity and excellent thermal insulation. By minimizing thermal bridging and heat transfer, they help maintain consistent internal temperatures in refrigerated trucks, reducing the energy load on cooling systems. With high compressive strength and fatigue resistance, these cores withstand the vibrations and stresses of heavy-duty transport, extending panel lifespan and enhancing safety.

Buses and Mass Transit Vehicles

In public transportation—such as buses, Electric Multiple Units (EMUs), and Mass Rapid Transit (MRT) vehicles—composite foam cores play a vital role in floor, ceiling, and wall panels. Their lightweight nature reduces overall vehicle mass, improving energy efficiency and reducing wear on infrastructure. Fire resistance and mechanical robustness safeguard passengers while ensuring compliance with strict regulatory standards. At the same time, superior thermal and acoustic insulation improves passenger comfort.

Railway and High-Speed Trains

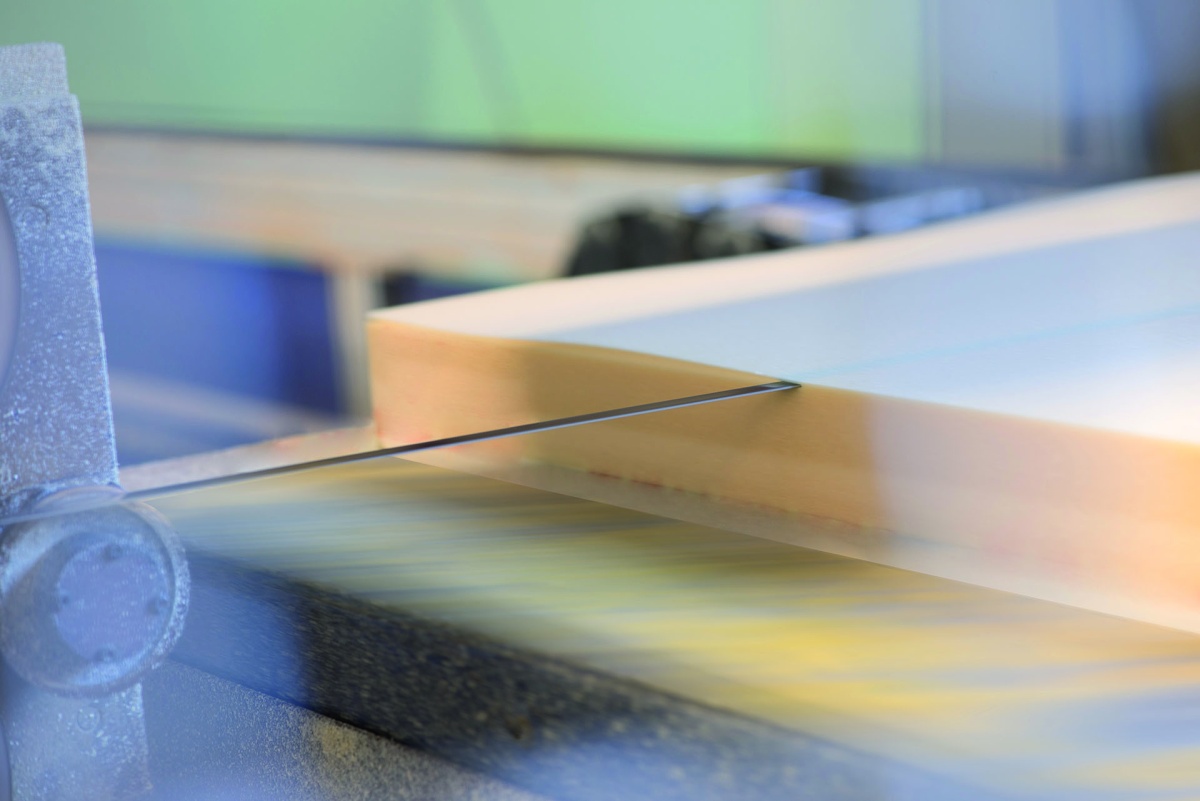

High-speed trains and light rail systems benefit from the exceptional strength-to-weight ratio and durability of composite foam cores. Resistant to moisture and chemicals, these cores help maintain structural integrity under challenging environmental conditions. Their ability to be thermoformed and CNC-machined into complex geometries allows for design flexibility in aerodynamic and noise-reduction features essential to modern rail transport.

Marine and Commercial Boats

In both commercial and recreational boat building, composite foam cores are used extensively in decks, bulkheads, and superstructures. They offer high impact resistance, excellent fire safety ratings, and superior resistance to water ingress. Their low weight reduces vessel draft and improves fuel efficiency, while mechanical toughness ensures durability against dynamic marine forces.

Customized Core Kitting Services

To support complex projects, Sky Composites offers customized core material processing services. Pre-cut, precision-shaped foam core kits come with detailed labeling and assembly instructions, enabling streamlined production with reduced waste and consistent quality. These tailored kits adapt to diverse vehicle geometries and manufacturing requirements, boosting operational efficiency and allowing manufacturers to optimize their assembly processes.

Building lighter and stronger vehicles with our composite foam cores

As transportation evolves, composite foam cores are central to creating lighter, safer, and more sustainable vehicles. With PVC and PET foam cores, manufacturers gain lightweight yet durable solutions that enhance performance, extend service life, and support environmental goals through recyclability and reduced emissions. Committed to innovation, Sky Composites develops advanced materials tailored to the transport industry, helping create vehicles that are not only stronger and lighter but also more efficient and sustainable for the future.