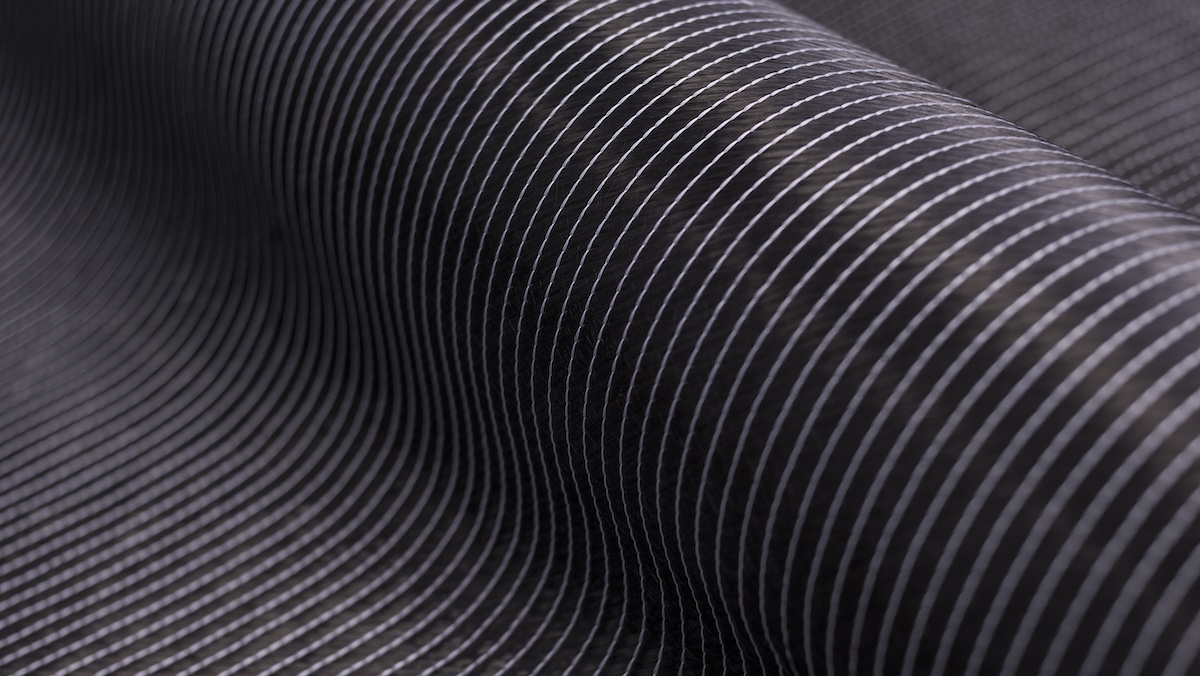

Traditional woven fabrics interlace fibers, which can introduce crimp and limit fiber efficiency in high-performance structures. Carbon non-crimp fabrics (NCF), also called multiaxial fabrics, solve this by laying 1–4 layers of unidirectional carbon fibers in load-aligned orientations (typically 0°, 90°, ±45°) and stabilizing them with a stitched, non-crimp architecture so the fibers stay straight. We supply these multiaxial configurations (unidirectional, biaxial, triaxial, quadriaxial) to help engineers hit a better strength-to-weight target with tailored layups and solid processing behavior. Alongside carbon multiaxials, we also supply warp-knitted fiberglass NCFs for applications where processability, permeability and cost-performance are key drivers.

The Technical Advantages of Carbon Non-crimp Fabrics (NCF)

- No “crimp” effect: Multiaxial (NCF) fabrics keep the fiber paths straight (not bent/crimped as in woven fabrics), which maximizes load-bearing capacity and improves tensile strength, stiffness, and fatigue resistance.

- Optimized resin flow: The architecture of NCF supports more consistent resin infusion and reliable wet-out (ideal for RTM and vacuum infusion processes).

- Customizable architecture (1–4 layers): We supply unidirectional (0°), biaxial (±45° or 0°/90°), triaxial (0°/+45°/−45°), and quadriaxial (−45°/90°/+45°/0°) options so reinforcement can follow real load directions.

- Weight reduction without “overbuild”: By tailoring fiber orientations and using a strong strength-to-weight approach, NCF helps achieve lighter laminates while maintaining structural performance.

Key Applications of Carbon NCFs Across Industries

Marine

In marine applications, multiaxial NCF carbon fabrics are commonly used in hulls, decks, and bulkheads because their straight, multi-angle fiber architecture delivers high stiffness and fatigue resistance under wave loads and torsional stresses. For large yachts and commercial vessels, we can support demanding structures with customizable multiaxial NCFs (1–4 layers) in heavier areal weights to meet high strength-to-weight requirements at scale.

Automotive & Transportation

In automotive and transportation, multiaxial NCF carbon fabrics are used for chassis parts, body panels/body structures, and structural reinforcements because their straight, non-crimped fiber paths improve load-bearing capacity and support durability and impact resistance compared to woven alternatives. We also work with applications tied to lightweighting, where reducing mass while maintaining crash-relevant structural integrity directly supports range and efficiency.

Wind Energy

In wind energy, multiaxial NCF carbon fabrics are a strong fit for turbine blades because the layup can be aligned with real blade loads: 0° plies for bending stiffness and ±45° plies to handle torsion and shear. NCFs keep fibers straight (no crimp), which boosts stiffness and fatigue resistance, and our multiaxials are available in 1–4-layer configurations (including ±45° options) specifically used for parts like wind turbine blades.

Sports & Leisure

In sports and leisure, we help manufacturers tune product “feel” by adjusting fiber orientations and areal weight, which directly influences stiffness and flex patterns. This approach fits premium equipment such as skis, snowboards, high-end bicycles, and ice hockey sticks, where brands target high stiffness-to-weight and repeatable performance.

Manufacturing & Customization at Sky Composites

At Sky Composites, our multiaxial fabrics are produced using non-crimp techniques like warp knitting and stitching, maintaining precise fiber orientation and consistent properties across our reinforcement range.

On the customization side, customers can specify fiber orientations, areal weights, stitching patterns, fabric width, and roll length—multiaxial NCFs available from 100 to 1600 gsm for anything from lightweight to heavy-duty laminates.

Warp-Knitted Fiberglass NCF (Non-Crimp Fabrics)

Sky Composites also offers warp-knitted fiberglass non-crimp fabrics (NCF) designed for demanding composite parts where you need high strength with low weight and reliable processing. These NCFs combine customizable fiber orientations with excellent mouldability and permeability, supporting efficient resin flow for complex geometries, while helping maintain high fiber content and strong mechanical properties (strength, stiffness).

They’re used across marine, sports equipment, rail transportation, automotive, construction, and wind energy, and are engineered for a smooth finish by minimizing print-through.

Sky Composites for Tailored Non-crimp Fabric Reinforcements

Non-crimp fabrics are a core building block for modern lightweight engineering: straight fibers, multi-angle strength, and efficient processing unlock lighter structures without giving up mechanical performance. As industries keep pushing for efficiency and lower material waste, multiaxial NCFs will stay a top choice for structural design. Browse our carbon and fiberglass fabric range, or contact us to align a custom reinforcement spec with your loads, process, and target weight.