Modern boat building relies on lightweight and durable boat composite materials to achieve strength, fuel efficiency, and long-term performance. Traditional materials like wood and steel are heavy and require more maintenance, while advanced composites offer superior resistance and flexibility. Among these, PVC foam cores stand out as high-performance solutions, providing excellent strength-to-weight ratio, water resistance, and design versatility for modern marine applications.

Why choose PVC foam core in modern boat composite materials?

PVC foam cores are a proven solution in sandwich composite construction, delivering the strength and durability boat builders need without adding unnecessary weight.

By providing a superior strength-to-weight ratio, PVC cores improve performance, handling, and fuel efficiency, while their impact resistance and fatigue tolerance ensure reliability in rough marine conditions.

The closed-cell structure resists moisture, chemicals, and saltwater, preventing rot and degradation over time. Compared with PET foam and balsa wood, PVC offers better impact resistance, easier machining, and superior moisture protection, making it the preferred choice for today’s marine engineers and boat builders seeking reliable composite solutions.

Technical advantages of PVC foam cores

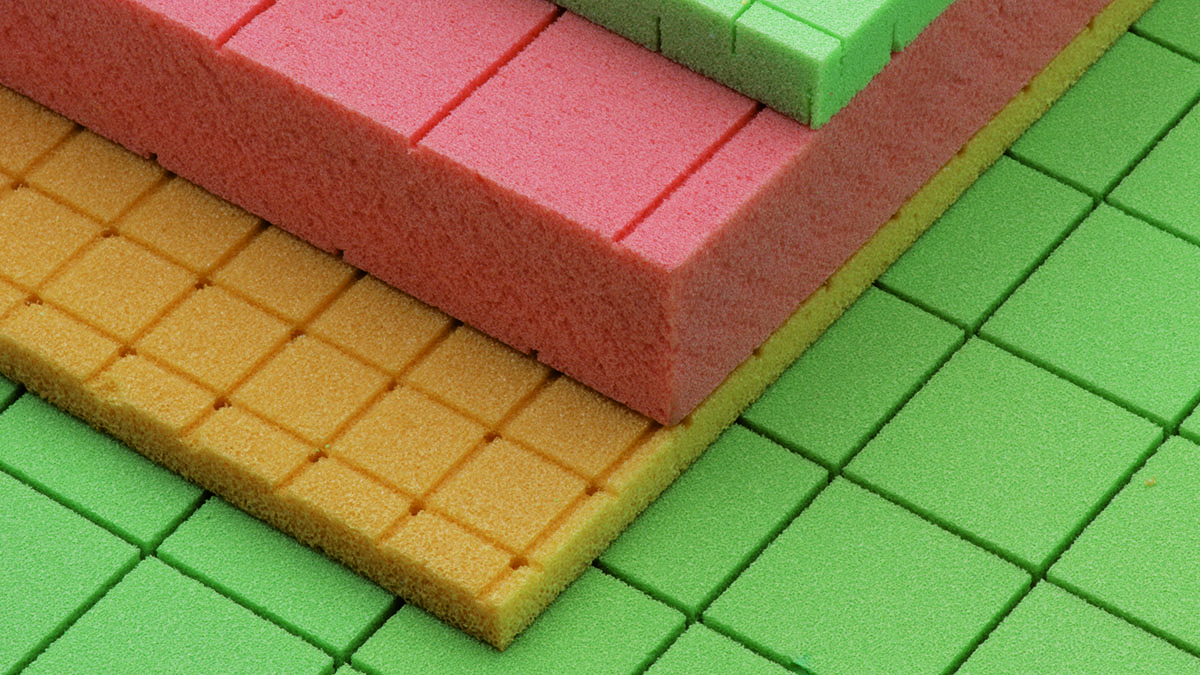

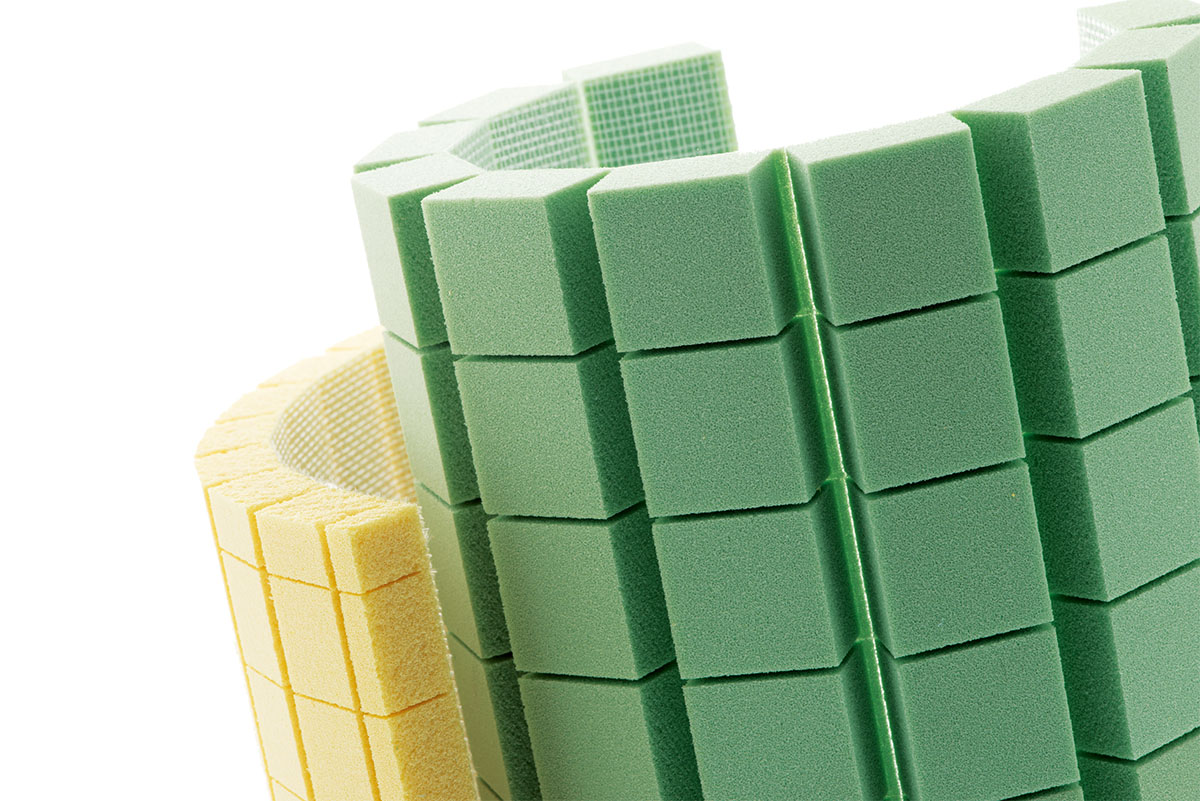

Sky Composites’ PVC foam cores deliver a unique combination of benefits that make them ideal for modern marine applications. Their closed-cell structure ensures excellent water resistance and low resin uptake, preventing swelling or rot while reducing production costs. With high shear and compression strength, they provide stiffness and structural integrity for hulls, decks, and bulkheads under demanding loads. The materials are also thermoformable, enabling complex curves and innovative boat designs without compromising strength. In addition, their dimensional stability under temperature changes, UV exposure, and moisture stress ensures long-term precision and fit. By resisting decay and mildew, these foams lower maintenance needs and extend the service life of marine structures.

Sky Composites PVC Foam Core Product Range

To meet diverse boat-building requirements, Sky Composites offers several specialized PVC foam core types:

- MYcell Rigid PVC Foam Core – A closed-cell, cross-linked rigid foam with high stiffness and strength for hulls, decks, and bulkheads, DNV certified for marine use.

- Flexcell Impact Load PVC Foam Core – A flexible, thermoformable core designed to absorb dynamic loads and deliver toughness in curved or contoured structures.

- HYcell Temperature Resistant PVC Foam Core – Maintains performance under elevated curing temperatures, ideal for prepreg and advanced marine applications.

- Flexcell-ECO Recycled PVC Foam Core – A sustainable option made with recycled PVC that preserves essential mechanical properties for eco-friendly boatbuilding.

Processing and customization for efficient boat building

Sky Composites offers advanced core material processing capabilities for PVC foam cores, including precision cutting, grooving, CNC shaping, and finishing. These techniques enable the creation of complex, contoured parts and multi-density kits while improving resin flow and bonding during lamination.

Pre-cut and precision-shaped cores help boat builders save time on assembly, reduce labor costs, and minimize material waste by ensuring accurate, repeatable shapes in boat composite structures.

In addition, Sky Composites provides extensive customization options such as tailored thickness, density, and finishing treatments, along with kitting services that package components for streamlined production. With processing facilities located across Europe, Asia, and North America, customers benefit from fast delivery and localized support for their marine projects.

Applications of PVC foam cores in boat building

PVC foam cores are essential in hulls, decks, bulkheads, and superstructures, reducing weight while adding stiffness, durability, and impact resistance. They are used in yachts for better fuel efficiency and comfort, in fishing boats for corrosion resistance and low maintenance, and in motorboats or sport boats for agility and resilience. Thanks to their thermoformability and CNC machining, PVC foam cores also enable innovative marine designs with complex shapes, supporting both high-volume production and custom builds.

Advanced boat composite materials from sky composites

PVC foam cores are now a cornerstone of modern boat composite materials, combining lightweight strength, durability, and design flexibility to meet the demands of today’s marine industry. With advanced processing, proven performance, and certified quality, we offer boat builders a reliable path to efficiency and innovation.

Sky Composites delivers customized, high-performance composite solutions tailored to marine applications, helping shipyards and designers achieve superior results. Contact us to discover how our PVC foam cores can power your next boatbuilding project.