PVC foam core is a well-established material in the composites world, known for its strength-to-weight ratio, durability, and adaptability.

In this article, we’ll break down

- what makes PVC foam such a reliable choice in structural applications,

- how it compares to alternatives like PET and balsa,

- and where it delivers the most value.

You’ll also learn how precision processing—cutting, grooving, and kitting—can optimize both performance and production efficiency across sectors like marine, wind energy, and transportation.

PVC foam core is known for its strength-to-weight ratio.

Structure, key properties, and their benefits

Like PET foam, PVC foam core features a closed-cell structure that resists water absorption and supports strong adhesion to resin systems.

The mechanical properties of PVC are similar in stiffness and compression strength, but PVC also brings higher impact resistance and elongation making it more forgiving in high-stress or vibration-prone environments.

Its thermoplastic nature allows it to be machined, grooved or thermoformed into complex geometries, supporting both flat and curved composite assemblies.

These characteristics make it especially valuable in marine and wind energy sectors, where fatigue resistance and shaping flexibility are critical.

Main applications of PVC foam core

PVC foam core is used across diverse industries requiring lightweight, durable sandwich structures:

- Marine: on decks, bulkheads and superstructures where moisture, impact and fatigue resistance are essential.

- Wind energy: within blade and nacelle kits that require light yet strong material across aerodynamic surfaces.

- Transportation and rail: in floors, ceiling panels and door cores where consistent structural integrity is needed.

- Construction and industrial: for insulated panels, tooling boards and cladding, benefiting from PVC’s dimensional stability and low resin intake

PVC foam core is applied across diverse industries.

When is PVC preferred?

Compared to PET, PVC is the better choice when your application involves high vibration, complex curves, or impact loads. It machines more easily and handles dynamic stresses with more resilience.

While PET remains a cost-effective, recyclable option for flat and rigid parts, PVC suits projects requiring shape adaptation and stress tolerance.

Against Balsa, PVC offers uniformity and moisture resistance that wood simply can’t match. There’s no risk of rot or inconsistent density.

And in CNC applications, PVC offers smoother, cleaner results with no grain, no splintering.

How PVC foam core is processed: from block to tailored finish

Sky Composites sources high-grade PVC foam—such as Maricell’s DNV-certified material—and transforms it into application-ready core products through advanced processing techniques.

- Cutting and slicing: blocks and sheets are precisely cut to your specified thickness.

- Grooving and piercing: enhances resin flow and surface compatibility.

- CNC shaping: enables production of curved panels, contoured parts and multi-density kits.

- Dedicated QA: strict in‑house inspection ensures each piece meets tolerances and performance benchmarks.

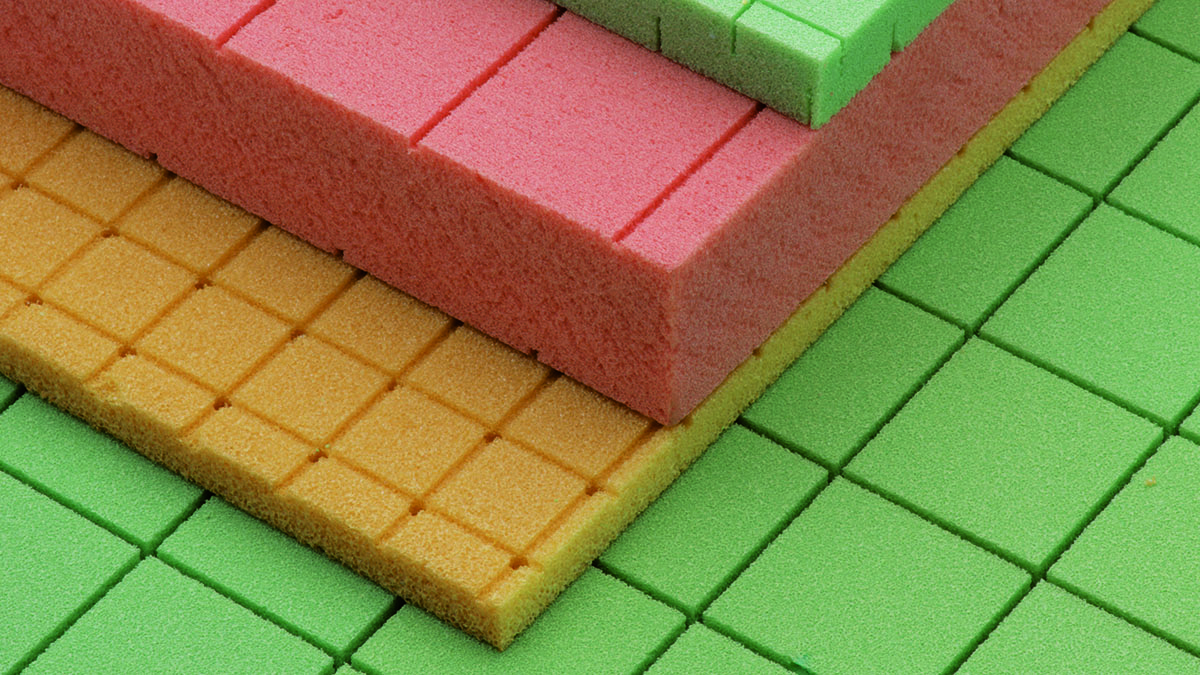

PVC foam core processed through cutting, grooving, and CNC shaping for composite applications.

Boost efficiency with kitting & pre-cut core materials

For complex builds and high volumes, pre-cut kits drive efficiency. Sky supplies foam kits designed to match the contours of blades, hulls and panels.

These kits:

- Reduce manual labor, cutting out time-intensive trimming.

- Cut material waste by producing exact shapes with minimal off-cuts.

- Ensure repeatable accuracy, even for intricate geometries.

This makes pre-shaped cores ideal for wind blade segments and marine panel sets.

Why choose Sky Composites for your PVC foam core needs?

Sky Composites offers a compelling combination of product quality and processing capability:

- Certified materials: including DNV- and ISO9001-rated rigid, impact, high-temp and eco-core options.

- Broad stock and fast delivery: large inventory enables short lead times.

- Versatile finishing: from slicing to CNC kits, all in one streamlined workflow.

- Global service: supported by expertise and facilities across Europe, Asia and North-America.

Explore our PVC product range

Sky Composites offers four distinct PVC foam core solutions each developed to meet specific structural, thermal, and sustainability needs in composite applications.

- MyCell – A rigid, lightweight PVC foam core with a closed-cell structure, ideal for sandwich panel construction. DNV-certified and engineered for consistent performance, MyCell is well-suited to marine, transportation, and industrial uses where strength, dimensional stability, and moisture resistance are critical.

- FlexCell – A flexible, impact-resistant core designed for dynamic environments. FlexCell’s thermoformability makes it perfect for curved or contoured structures like boat hulls, vehicle panels, or energy components that need to absorb vibration and handle repeated stress.

- HyCell – A high-temperature-resistant PVC foam core tailored for advanced manufacturing. Compatible with prepregs and other high-temp resin systems, HyCell maintains mechanical stability even in elevated cure cycles—ideal for aerospace, motorsport, or tooling applications.

- FlexCell Eco – A more sustainable choice that doesn’t compromise on performance. FlexCell Eco incorporates recycled content and offers the same closed-cell strength, toughness, and processability as standard PVC foam, supporting eco-conscious manufacturing goals without sacrificing material reliability.

Each core is available with customized thicknesses and finishing options—grooved, perforated, or CNC-shaped—so you get exactly the performance your project requires.

Conclusion

PVC foam core continues to be a dependable and adaptable solution for structural composites—especially when performance, processability, and precision matter.

With a range of certified products and advanced finishing capabilities, Sky Composites is ready to support your next project.

Contact our team today or download our brochure to learn more or request tailored solutions for your application.