Foam core materials are essential in industries where every gram matters, combining low density with structural strength to create lightweight yet durable components. Within this category, thin foam core sheets stand out for reducing weight while maintaining stiffness and dimensional stability—qualities that make them especially valuable in aerospace, UAV, and model aircraft applications.

Ultra-thin PVC foam sheet

Why thin foam core sheets matter

Beyond being lightweight and strong, thin foam core sheets deliver exceptional dimensional accuracy, ensuring consistent and reliable performance in precision manufacturing. This makes them indispensable where tolerances are tight and quality cannot be compromised.

They are also a cornerstone of micro-sandwich constructions, where a thin foam core layer is placed between carbon fiber or fiberglass fabrics. This design greatly enhances structural efficiency, resulting in components that carry demanding loads while staying remarkably light.

Equally important is their customization potential: thin foam cores can be produced in ultra-thin dimensions and adapted to the exact requirements of aerospace, UAV, and model aircraft structures.

From complex geometries to tailored finishes, customization makes it possible to meet the strictest performance and weight reduction goals.

Sky Composites’ thin foam core solutions

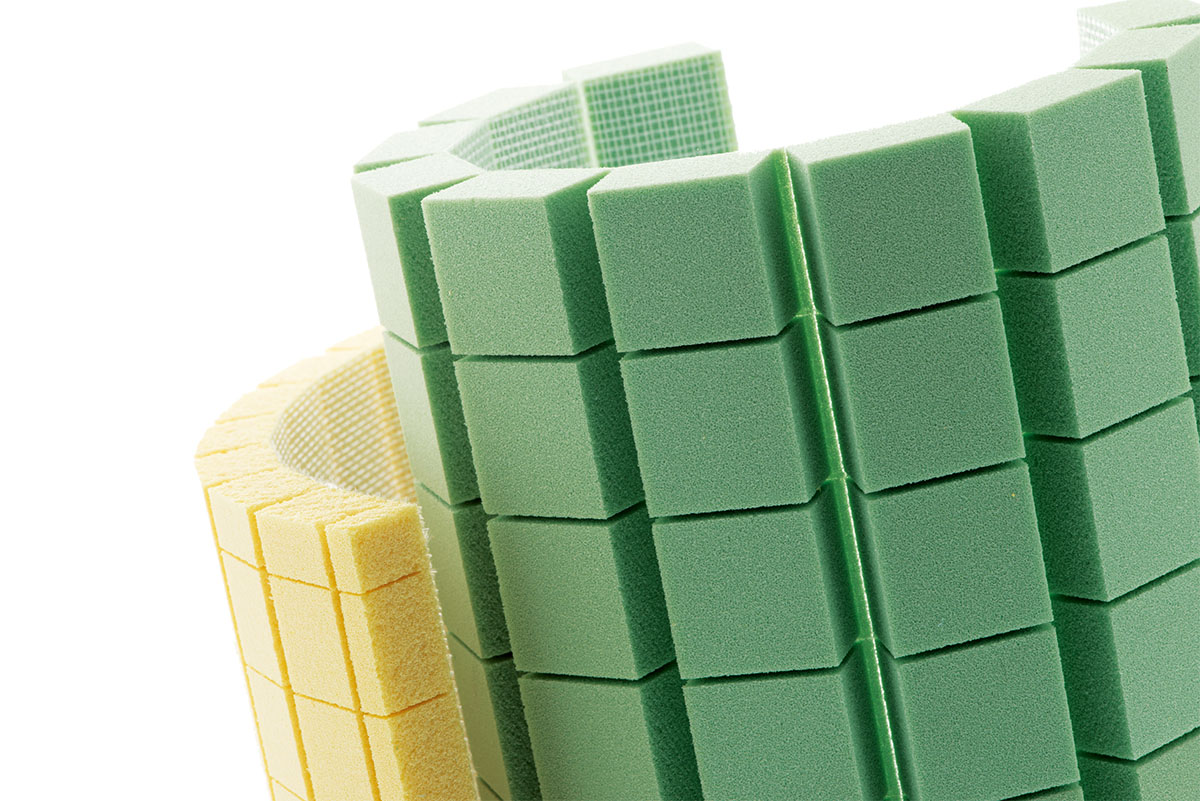

Sky Composites offers a broad range of advanced foam core materials. Our portfolio includes:

- PVC foam cores – versatile and balanced in performance,

- PET foam cores – recyclable with strong thermal stability,

- PMI foam cores – excellent mechanical strength and heat resistance,

- Balsa cores – a natural option with outstanding stiffness-to-weight ratio.

Our ultra-thin foam cores, available in thicknesses as low as 1 mm (as well as 1.5 mm, 2 mm, and 3 mm), provide exceptional durability with ultra high precision (thickness tolerance of only +/- 0,5 mm).

This precision ensures consistent dimensional accuracy and smooth integration into complex composite structures.

Typical applications include UAV and drone body panels and blades, aerospace interior components, and model aircraft structures, where even the smallest weight savings translate into improved efficiency and performance.

Core material processing & customization services

Sky Composites’ global processing facilities provide advanced core material processing services such as cutting, grooving, and perforation, ensuring optimal resin flow and excellent formability. These capabilities help manufacturers achieve stronger, more efficient composite structures with minimal waste.

We also offer pre-cut core kits tailored to specific molds and production needs—even with ultra-thin foam cores. These kits simplify assembly, reduce production time, and ensure a perfect fit. In addition, customized finishes minimize resin consumption, cut costs, and deliver lighter, higher-quality components.

Core material processing

Market trends & future outlook

The demand for lightweight, high-performance materials is rising across aerospace, UAV, and model aircraft industries, with thin foam cores improving fuel economy, flight range, and payload capacity. Looking ahead, they will play a key role in sustainable aviation by enabling lighter, stronger sandwich constructions and adapting to next-generation manufacturing technologies.

Trusted Partner in Thin Foam Core Materials

Thin foam core sheets are vital for creating lightweight yet durable composite structures. With internationally recognized certifications (GL, DNV, ISO), a reliable global supply chain, and expertise in ultra-thin customized solutions, Sky Composites ensures the precision and performance needed for next-generation, energy-efficient designs.