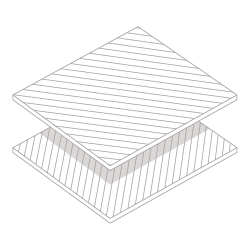

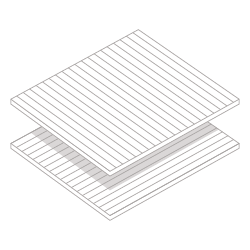

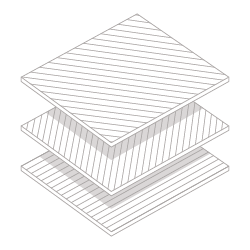

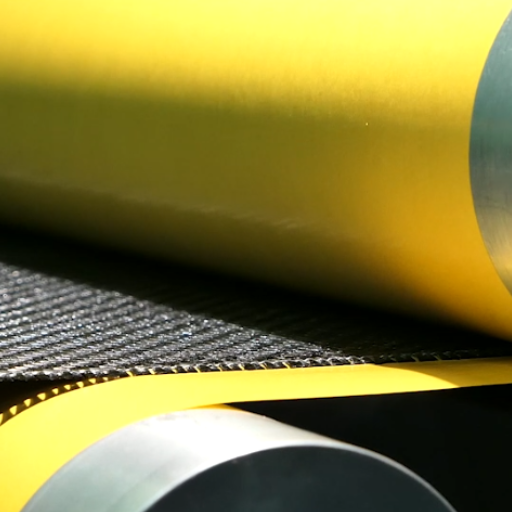

Premium pre-impregnated composite (pre-preg) fabrics

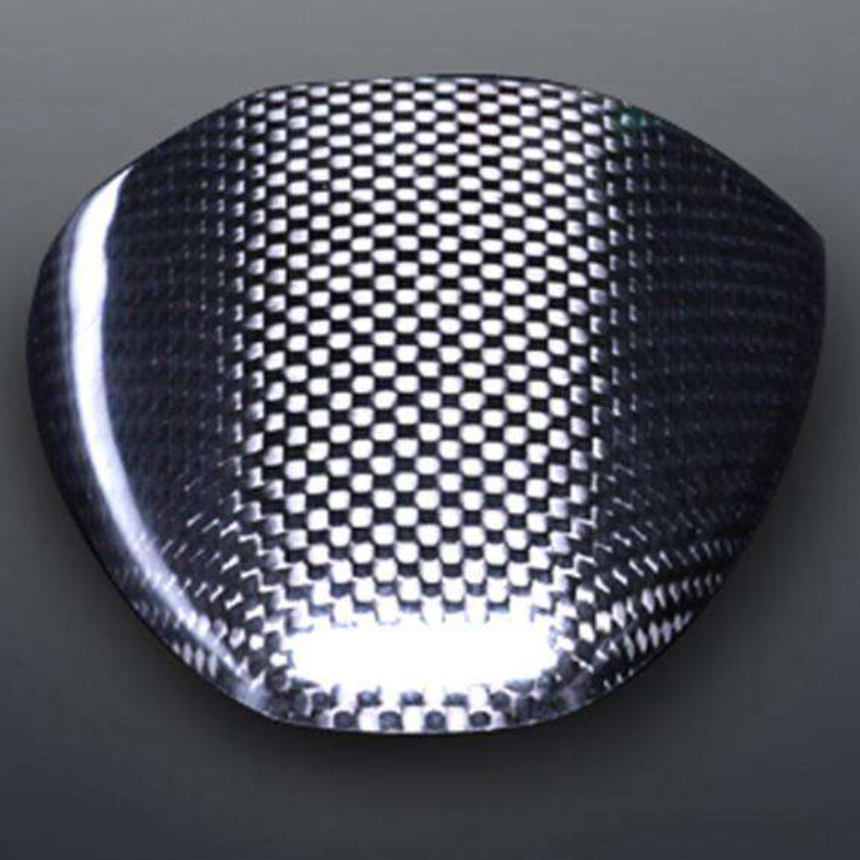

Sky Advanced Materials specializes in manufacturing high-performance carbon fibre fabrics, which serve as a key material for prepreg manufacturers. The pre-pregs designed to deliver unparalleled strength, lightweight performance, and exceptional precision. Prepregs are tailored to meet the exacting requirements of industries such as aerospace, automotive, marine, and industrial manufacturing, ensuring consistent quality and optimal performance in every application.

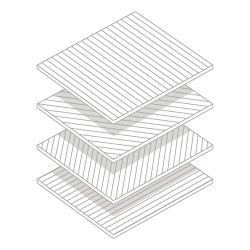

Crafted using advanced manufacturing techniques, prepregs from Sky advanced’s carbon fabrics provide precise resin content, excellent fiber orientation, and superior mechanical properties. These features make them ideal for producing lightweight structural components, high-strength parts, and innovative designs, enabling manufacturers to achieve exceptional results efficiently.