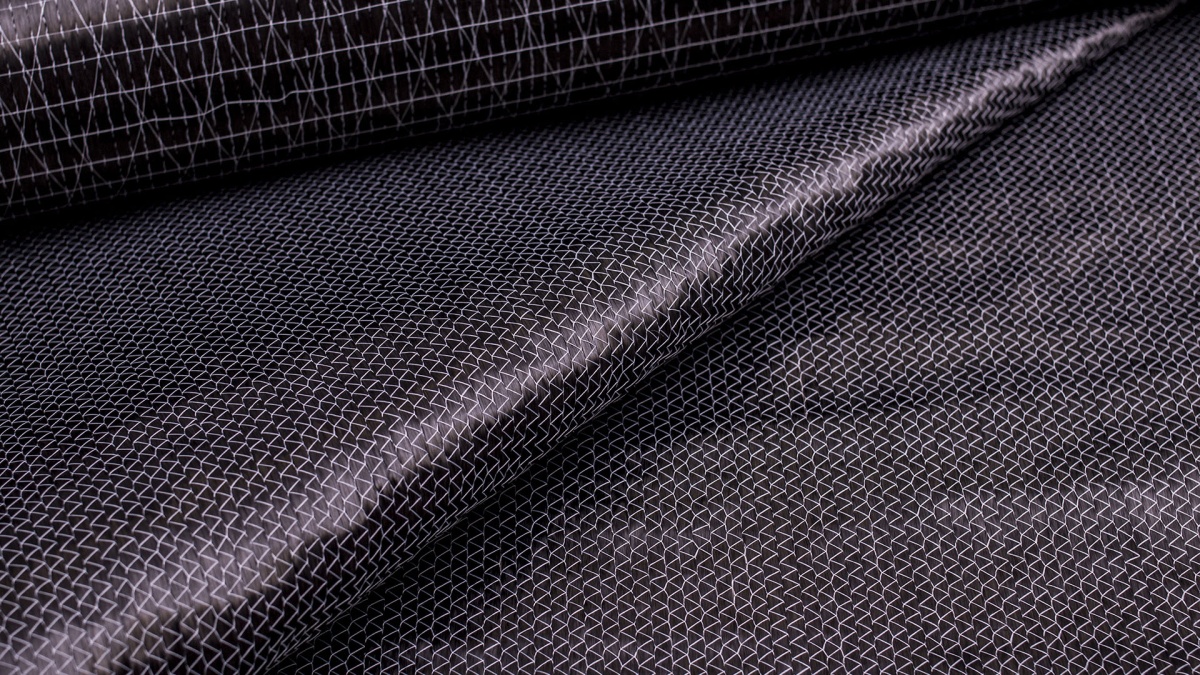

Multiaxial carbon fiber fabrics are redefining how engineers approach strength, efficiency, and lightweight construction.

Built for demanding environments, they deliver superior load-bearing capability without the mass associated with metal or traditional reinforcement systems.

Among advanced reinforcement materials, multiaxial carbon fiber fabrics stand out, engineered to manage complex stresses with a high strength-to-weight ratio.

In this article, we’ll cover:

- what makes multiaxial carbon fiber fabrics different

- key benefits for large-scale structures

- common applications across industries

- how processing methods impact performance

If you’re designing smarter, lighter structures, this material delivers on every front.

What makes multiaxial carbon fiber unique?

Unlike traditional woven fabrics, which interlace fibers in two directions (plain or twill pattern), multiaxial fabrics align fibers in multiple orientations—like 0°, ±45°, 90° and more—within the same laminate.

This non-crimp, stitched architecture maintains fiber integrity and creates uniform mechanical performance across several axes.

The result? Improved load distribution, minimized weak points, and increased flexibility for custom laminate design.

Why is it ideal for large structures?

When applied to large-scale components, multiaxial carbon fiber fabrics offer several key advantages:

- Superior strength-to-weight ratio: Lighter than metal alternatives while matching or exceeding their mechanical performance.

- Resists multidirectional forces: Perfect for structural elements exposed to complex stress patterns.

- Corrosion and fatigue resistance: Extends service life, especially in marine and outdoor environments.

- Design efficiency: Tailored fiber orientation reduces overdesign and material waste critical in large builds.

Applications across industries

Multiaxial carbon fiber fabrics are a go-to material in large-scale structural applications where lightweight strength, reliability, and long-term durability are essential.

Their ability to handle multidirectional loads makes them a smart choice across several demanding industries:

UAM, UAVs and transportation

In Urban Air Mobility (UAM), multiaxial fabrics are used for rotor blades, airframe structures, and lightweight interior components, where reduced mass and high stiffness directly support eVTOL performance and flight efficiency.

In UAVs and drone platforms, these fabrics deliver exceptional strength-to-weight ratios for arms, fuselage assemblies, and payload structures, improving flight endurance and maneuverability while maintaining structural robustness.

In the automotive and rail sectors, they support EV battery enclosures, chassis components, and body structures, helping reduce overall vehicle weight while maintaining crash resistance and structural integrity.

Marine

For boat hulls, decks, and bulkheads, multiaxial carbon fiber provides excellent stiffness, fatigue resistance, and corrosion protection in harsh marine environments.

Its multidirectional strength also improves performance under wave loads and torsional stresses, critical in high-performance and commercial vessels alike.

Infrastructure and construction

In civil engineering, these fabrics are applied to bridge strengthening, seismic retrofits, and structural rehabilitation of buildings.

Their lightweight nature simplifies installation, while the multi-angle fiber architecture ensures effective reinforcement against a variety of dynamic and static loads making them ideal for aging infrastructure upgrades and new construction projects alike.

Manufacturing methods that drive performance

At Sky Composites, our multiaxial fabrics are produced using advanced non-crimping techniques like warp knitting and stitching, maintaining precise fiber orientation for consistent mechanical properties.

These fabrics are compatible with key composite manufacturing processes:

- Resin Transfer Molding (RTM): For high-strength, low-void components.

- Vacuum-Assisted Resin Infusion (VARI): Enables large-scale part production with clean, repeatable results.

Together, material and method ensure optimal resin flow, strong fiber bonding, and maximum in-use performance.

FAQ

What are the limitations of multiaxial carbon fiber fabrics?

Additionally, due to their stitched structure, they may introduce slight resin-rich areas around stitching points though this is typically minor with proper processing.

How do multiaxial fabrics affect resin flow during infusion?

How customizable are multiaxial carbon fiber fabrics for specific projects?

Stronger structures, lighter designs

Multiaxial carbon fiber fabrics enable lighter, smarter structural designs without compromising strength or durability.

Whether you’re building the next aerospace component, marine vessel, or bridge retrofit, Sky Composites delivers the reinforcement materials engineered to perform.

Explore our range of carbon fiber fabrics and contact us to discuss your project needs.