The Evolution of Lightweight Structures

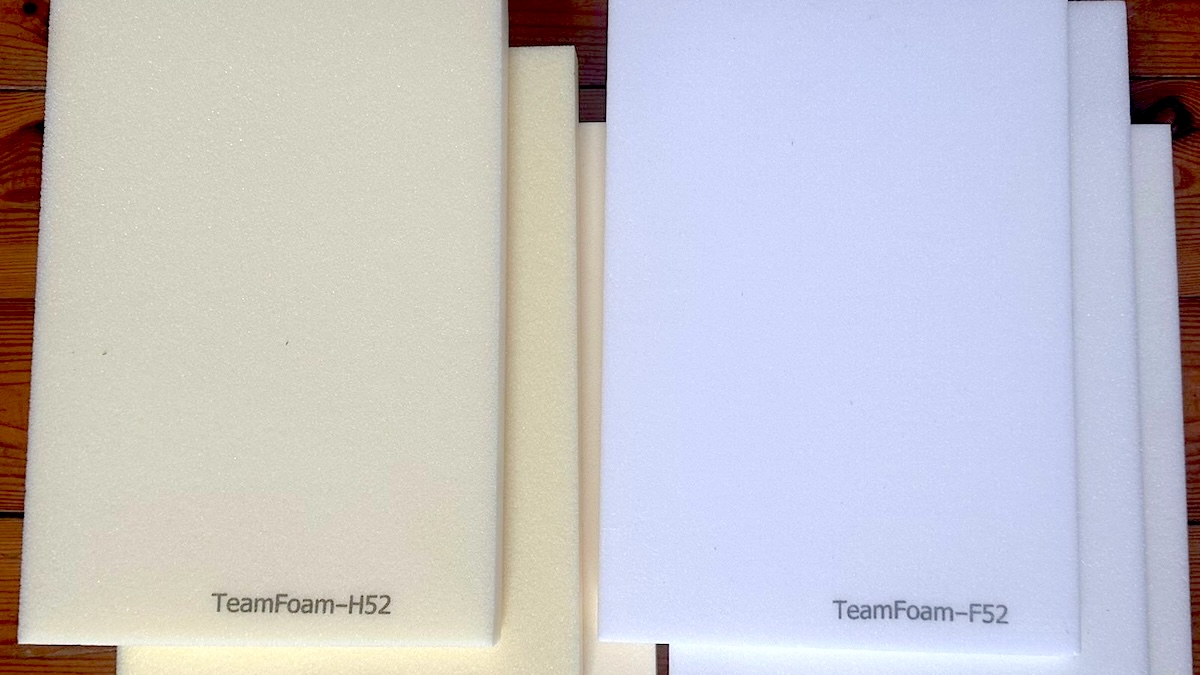

In advanced composite manufacturing, achieving the right balance between ultra-low density and structural integrity is a constant challenge. The Polymethacrylimide (PMI) foam sheet has become a widely used high-strength core solution designed to meet demanding requirements in the automotive and wind energy sectors. As a high-performance core material, it stands out for its mechanical properties and its ability to withstand elevated processing temperatures up to ~200°C (grade-dependent).

At Sky Composites, we provide PMI foam solutions that can improve impact and fatigue performance in sandwich structures and help optimize production efficiency through low resin uptake. Whether for intricate UAV components or sport equipment, the Polymethacrylimide (PMI) foam sheet is a strong option for lightweight, durable sandwich constructions.

What is Polymethacrylimide (PMI) Foam?

To understand why the Polymethacrylimide (PMI) foam sheet is considered a premium core material, it helps to look at its cellular architecture. At its core, PMI is a rigid, closed-cell structural foam. Unlike open-cell materials that can act like a sponge, PMI’s closed-cell structure means each tiny cell is sealed.

This structure helps minimize resin uptake during manufacturing processes such as vacuum infusion or RTM, keeping the final structure as light as possible and improving resin efficiency in the laminate and bondline.

Polymethacrylimide foam sheet properties: thermal stability, strength and dielectric performance

- Thermal Stability: One of the standout features of a Polymethacrylimide foam sheet is its extreme heat resistance. While many core materials soften or deform at high temperatures, Sky’s PMI solutions can withstand processing temperatures up to ~200°C (depending on grade and process). This makes PMI a strong fit for prepreg curing cycles (often autoclave), where thermal stability is critical.

- Compressive Strength: Despite its ultra-low density, PMI offers excellent mechanical strength. It provides a rigid backbone for sandwich panels, with high resistance to deformation under load. This supports components designed for demanding environments such as rail transit and motorsport applications.

- Dielectric Properties: For electronics and telecommunications-related use cases, Polymethacrylimide (PMI) foam sheet has a low dielectric constant and low loss, which can support RF-transparent parts (e.g., radomes, antenna covers).

- Safety and Sustainability: Beyond performance, the material is available in grades designed for demanding fire performance requirements.

Why Choose Polymethacrylimide Foam Sheets?

When high performance is the priority, Polymethacrylimide (PMI) foam sheets can outperform common alternatives such as PVC and PET foams in applications where high-temperature processing and resin efficiency matter most.

- Weight & Resin Efficiency: Thanks to its fine, closed-cell structure, PMI helps avoid unnecessary resin uptake. This helps keep sandwich structures lightweight, as more resin remains where it is structurally useful—on the bonding surface and within the laminate—rather than wicking into the core.

- Ease of Processing: Despite its rigidity, PMI is easy to mill and CNC-machine. Sky Composites can support production with custom finishing services such as scoring, perforation, and grooving to enhance resin flow and formability.

The „Prepreg Advantage”

A key differentiator is thermal stability. While many commodity foams can struggle at elevated temperatures, a Polymethacrylimide (PMI) foam sheet can maintain integrity during prepreg curing cycles (often autoclave), up to ~200°C. In these processes, the core’s role is to provide dimensional support under pressure during cure to help maintain geometry and panel stability.

Engineering Applications: Where PMI Foam Sheets Shine

Polymethacrylimide (PMI) foam sheet is used across industries where “lightweight” and “heavy-duty” must go hand in hand. Examples include:

- Sports & Leisure: For athletes, gear weight equals performance. PMI can be used as a core in high-end hockey sticks, racing shells, and ultra-light bicycle frames. Its fatigue resistance helps these products handle repetitive stress.

- Automotive: In supercars and electric vehicles, reducing overall vehicle mass supports performance and efficiency targets. PMI can be integrated into carbon fiber-reinforced parts, providing rigid, heat-resistant cores for hoods, spoilers, and selected structural components.

Processing and Handling Tips

The dimensional stability of Polymethacrylimide (PMI) foam sheet supports precision fabrication, making it a good choice for high-tolerance CNC milling and cutting.

Beyond machinability, PMI is commonly used with epoxy and can be compatible with multiple resin systems.

For complex geometries such as curved UAV components, sheets can be thermoformed under controlled heat to achieve contoured shapes when processed correctly, while maintaining strong mechanical performance.

To optimize production, Sky Composites offers core material processing services, including custom kitting and finishing solutions designed to streamline assembly.

Sustainability and Efficiency in Production

Using a Polymethacrylimide (PMI) foam sheet can improve production efficiency and support sustainability goals in application-dependent ways. PMI’s fatigue resistance can contribute to longer product lifecycles, reducing the impact associated with frequent replacements.

Its closed-cell structure can also help prevent excessive resin uptake, which may lower material use and help keep parts lightweight. In transportation applications, weight reduction can contribute to improved fuel efficiency or lower operational energy consumption, depending on the design and duty cycle.

Elevating Your Composite Projects

Polymethacrylimide (PMI) foam sheet offers a strong combination of thermal stability and strength-to-weight ratio for demanding composite structures. With high-temperature capability and resin-efficient closed-cell architecture, it is a compelling choice for high-performance sandwich construction.

Contact us today for technical consulting and discover how our high-performance materials can elevate your next project.